Updated Press Release Duplomatic

Press release: Attached the press release about the completion of acquisition of Duplomatic MS Spa by Daikin. Image above of the ceremony just held at Duplomatic HQ in Parabiago, Milan,…

Happy Birthday Duplomatic

Happy Birthday - 70 YEARS Happy Birthday to Duplomatic - Motion Solutions Started 70 years ago with hydraulic components, extending their skills to become a 360° motion solutions provider. From…

Press Release Duplomatic

Press release: Alcedo sells Duplomatic to Daikin Industries The GP, through Alcedo IV Fund, and Daikin Industries agreed on the sale of Duplomatic, a leading Italian player in the global Motion Solutions…

High Speed Valves

Valves with Agility and Speed Today more than ever our clients are asking us for help to increase their productivity, precision, automation and decrease costs. By remaining agile, we bring…

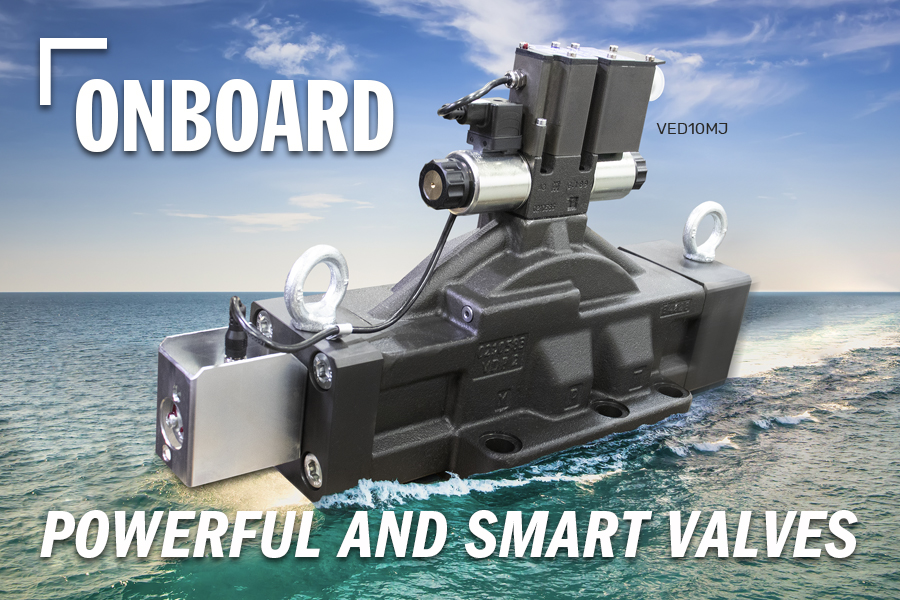

Every One Onboard

Powerful and smart proportional valves Like today’s Powerful and Smart Battleships, the Continental VED10MJ Proportional valve gets the job done. When total control and dominance over the load is required,…

NEW Industrial and Mobile Catalog

Continental and Hydreco working together As the world of Fluid Power evolves, so do we, at an increasingly faster pace. From hydraulics to motion and mobile solutions, from the mid-west…

Utility EXPO

Solutions in motion at the Utility Expo 2021 - Louisville, KY End of September, Continental and Hydreco attended The Utility Expo (formerly ICUEE) which is the largest event for utility…

Pumps – Vane / Piston / Gear

PUMPS: Vane / Piston / Gear Continental has been manufacturing variable volume, pressure compensated pumps since 1955! Our years of knowledge have resulted in some of the most robust, long…

The Utility EXPO 2021

Start planning to see us at The Utility Expo! Continental Hydraulics and Hydreco invite our distributors, customers, and prospects to view our newest products and technologies for mobile and industrial…

PVX Vane Pumps Are Quiet.

PowrFlow™ PVX Vane Pumps Are Quiet. PVX Vane Pumps are designed to be quiet. Our pumps make it easier to meet sound limits from the customer or the government. And,…