Directional Control Valves

Continental Hydraulics manufactures NFPA D03 to D10 size manifold mounted Directional Control Valves. With pressures to 5000 PSI continues duty and many function flow direction options, we have the correct valves for your application.

Solenoid / Soft-Shift / Hydraulic / Pneumatic / Manual Lever / Position Sensors

Solenoid Controlled – Direct Operated

Traditional solenoid - powerful and durable

Available in both D03 and D05 mounting patterns, the direct operated valves can be supplied for circuits requiring 2 or 3 positions, as well as 3-way or 4-way functions. The valve body is made with high strength cast iron and internal passages designed to minimize pressure drop.

- D03 pattern P, A & B ports to 5000 PSI, T port to 3000 PSI and nominal flows to 20 GPM

- D05 pattern P, A & B ports to 4600 PSI, T port to 3000 PSI and nominal flows to 38 GPM

- Solenoid connections – Conduit Box, DIN, Deutsch and Lead Wire options

Solenoid Controlled – Pilot Operated

Traditional solenoid - powerful and durable

The VSD*M and VPD*M pilot operated directional control valves are available with either electric solenoid or hydraulic actuation of the main spool.

The valves are available in both 2 or 3 position and various spool flow patterns. Configurable for internal or external pilot/drains and options for pilot pressure reducing, pilot chocks, and main stage stroke adjustments.

- D05H patterns P, A & B ports to 4600 PSI, T port to 3600 PSI and nominal flows to 40 GPM

- D07 pattern P, A & B ports to 5000 PSI, T port to 3600 PSI and nominal flows to 80 GPM

- D08 pattern P, A & B ports to 5000 PSI, T port to 3000 PSI and nominal flows to 125 GPM

- D10 patterns P, A & B ports to 5000 PSI, T port to 3000 PSI and nominal flows to 290 GPM

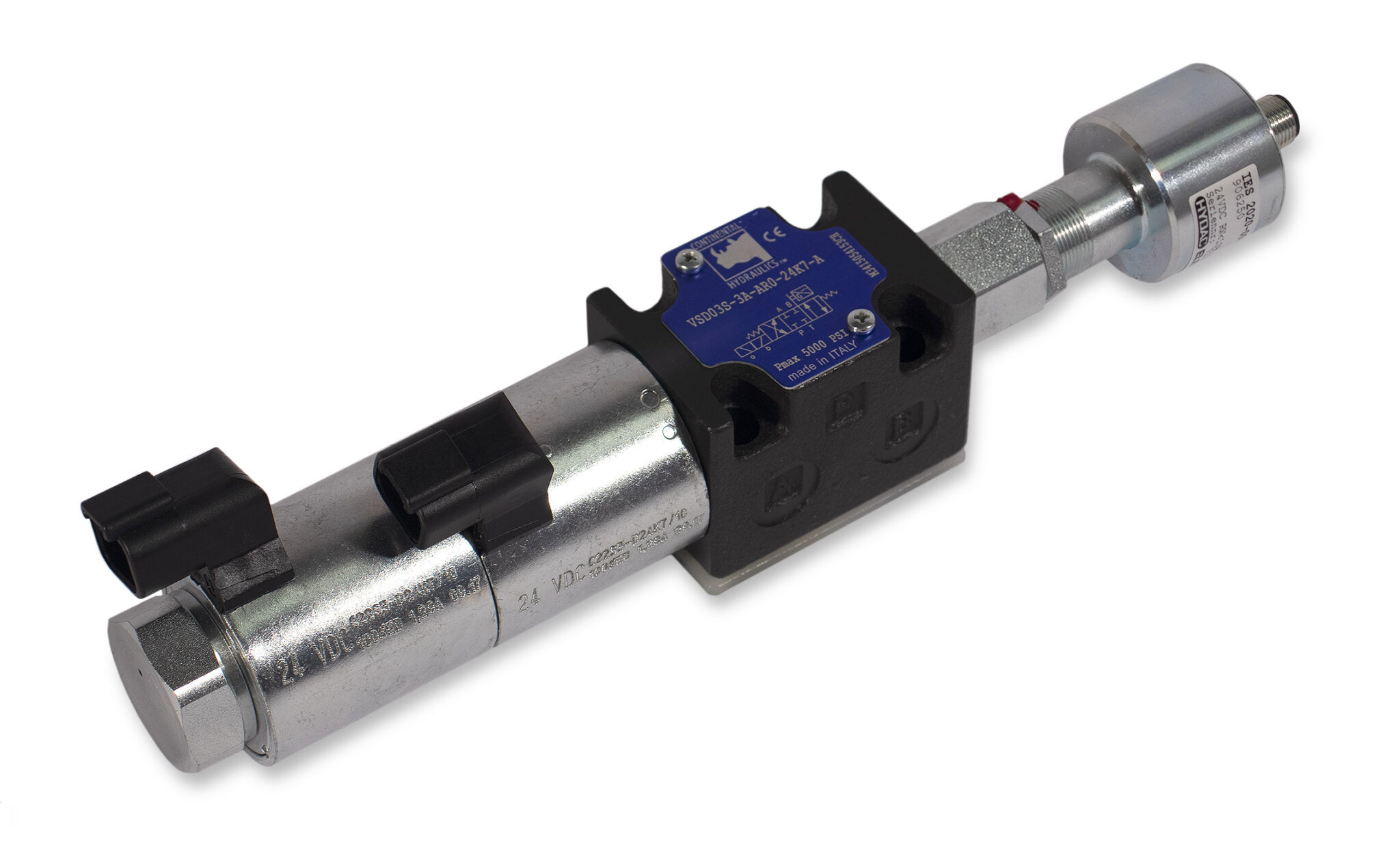

Position Monitored Solenoid Operated Valves and Kits

Helping meet safety requirements

Spool Position Monitored Valves can be used as a component to help meet compliance with current machine safety standards. These devices are only one part of an overall system and are intended to be combined with other safety rated components to provide energy isolation and/or energy dissipation. According to current safety standards, a Risk Assessment should be performed as a part of the component selection.

- TÜV certification body certifies the compliance of VSD0*S valves with the EC safety standards ISO 4413:2012, UNI EN 12622:2014, UNI EN 693:2001 +A2:2001, UNI EN 201:2010 and UNI EN 422:2009 with certificate TÜV IT 14 MAC 0043.

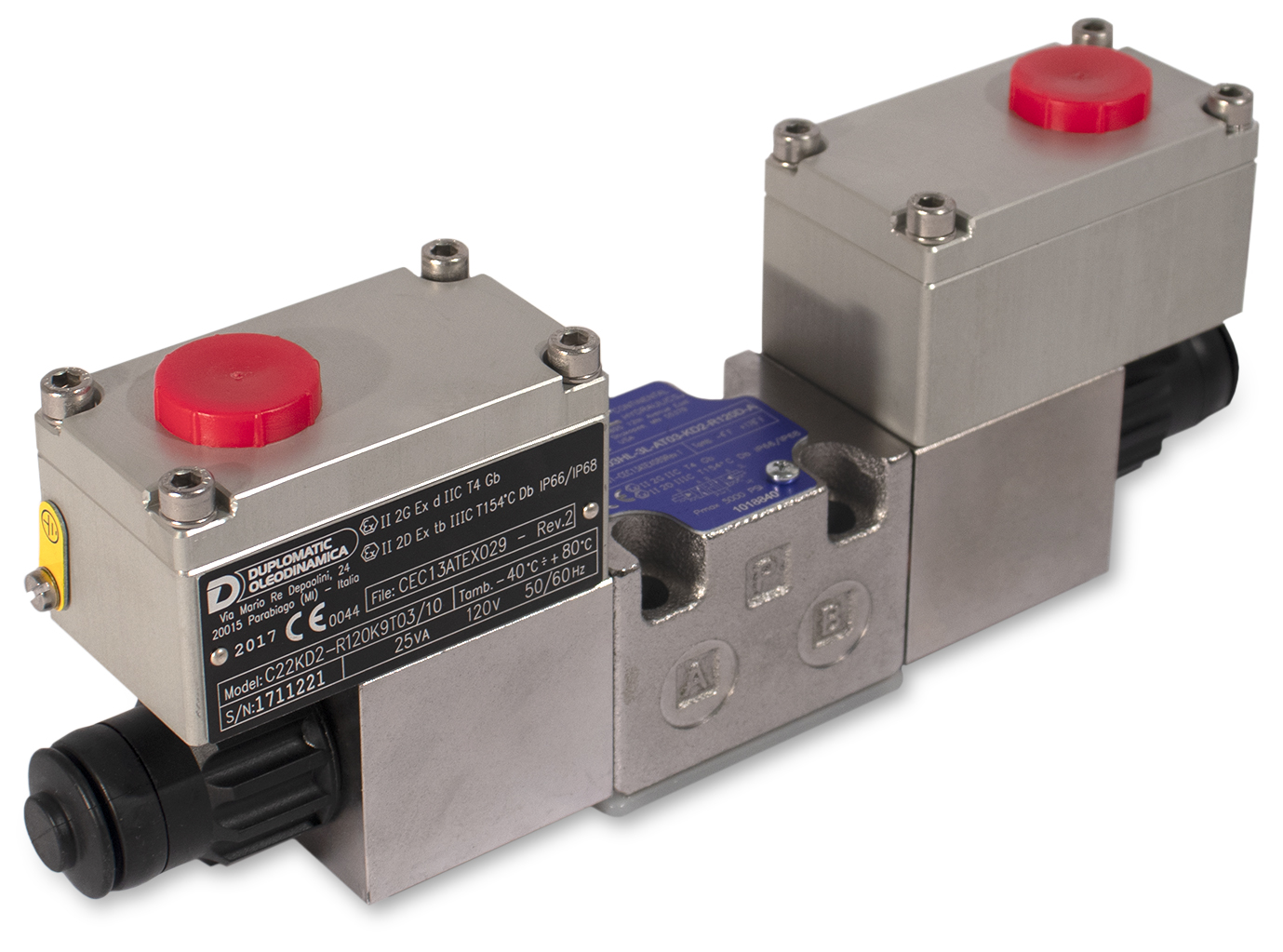

Explosion Proof - Hazardous Location Valves

Environments that require protection

The direct operated directional valves are available in ISO 4401-03 and ISO 4401-05 size; available pilot operated sizes are: CETOP P05, ISO 4401-05, ISO 4401-07, ISO 4401-08 and ISO 4401-10.

They are compliant with ATEX, IECEx and INMETRO, UL, CSA requirements and are suitable for use in potentially explosive atmospheres, for surface plants or mines.

- Low temperature version up to – 40 ° is also available.

- NFPA D03 and D05 valves are supplied with a zinc-nickel finishing surface treatment that ensures a salt spray resistance up to 600 h

- Pressure to 5000 PSI and flows to 290 GPM

Pneumatic - Hydraulic - Manually Operated

Lever, air or hydraulic actuators

Continental Hydraulics offers directional control valves with air pilot actuation, hydraulic pilot actuation and lever actuation. These valves conform to NFPA D03/D05 and ISO 4401 mounting standards. They are available in both 3 way and 4 way styles.

All versions are available in 2 position spring offset, 2 position detent, 2 position spring centered and 3 position spring centered versions. The lever valve also is available in a 3 position detent model.

- A wide range of spools is available.

- Air pilots to 175 PSI / Hydraulic pilots to 3000 PSI

- D03 to 5000 PSI / D05 to 4600 PSI rated